Success History

SOLUTION: TOTAL SOLUTION, “Containment, Support, Seal, Filtration, Collection and / or Suppression; Alignment and Cleaning “.

INDUSTRY: AGGREGATES

LOCATION:GARCIA, NUEVO LEONU

COMPANY: REGIOCAL

PROBLEM

The company REGIOCAL presented serious problems of spillage and extreme pollution in the conveyor of the furnace 2, which caused high maintenance costs, 6% loss of the finished material and its reprocessing, besides insecurity for the operators of the area. In addition, these spills caused damage to the components of the conveyor, delays in the process due to the need for constant cleaning, since a team of four people was assigned to prepare the area on both shifts daily, the problem of dust contamination has reached such degree that the company has received government sanctions.

SOLUTION

REGIOCAL contacted the company Martin Engineering to analyze the situation and find a solution to their problems. By means of an exhaustive analysis for the transporter through the Walking the Belt (WTB) program, it was determined that the side rails had very little dust settlement area, damage to the structure accentuated the leakage of fines, an improvised sealing system made of strip strips, which were placed along the conveyor resulting in inefficiency.

The incline of the conveyor was 20 ° and the transition zone was very short, this caused the material to undergo a backward movement, causing leaks.

A Total Solution proposal was made, in which various modifications required for the correct operation of the conveyor were recommended, the detailed engineering was delivered for the improvement and implementation of:

- Loading rails and side rails

- Specifications on skid plates

- Back box in the transfer chute

- Extension for band transition

In addition to the installation of the following Martin® equipment:

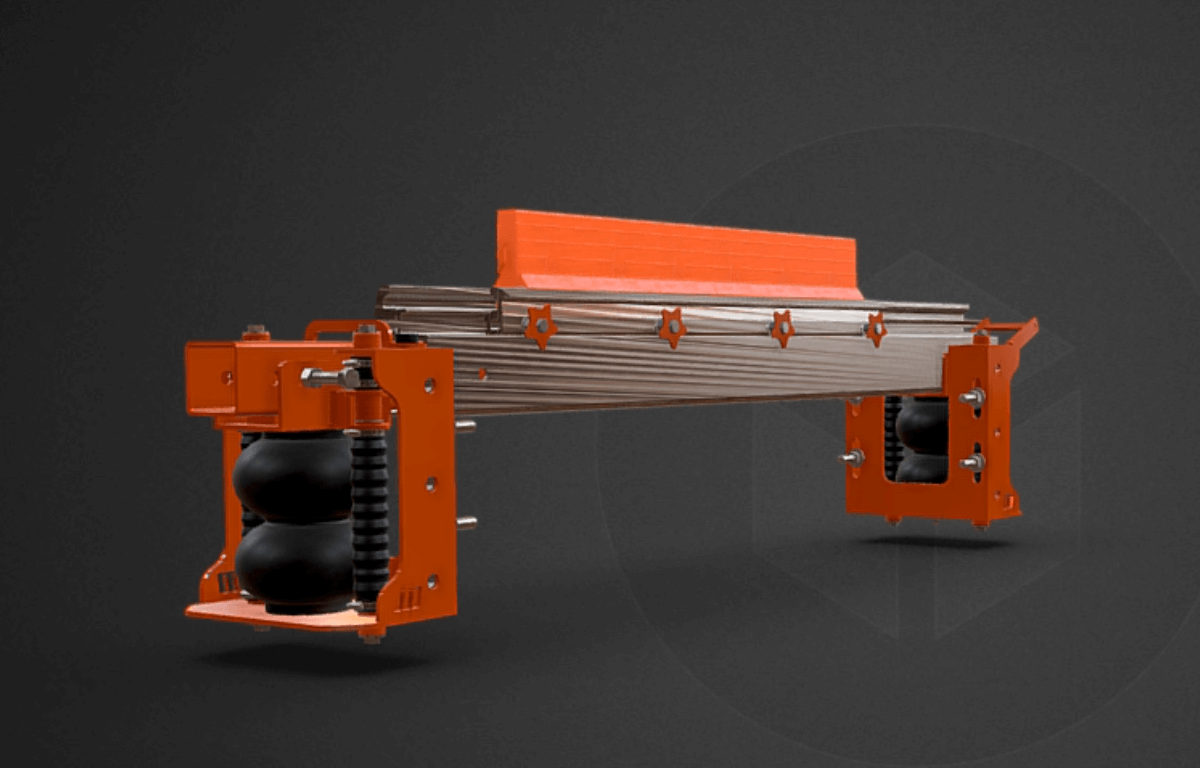

Band support.

- MD Bed Impact

- EVO® Sliding Bed

- Trac-Mount ™ Roller

Dust control.

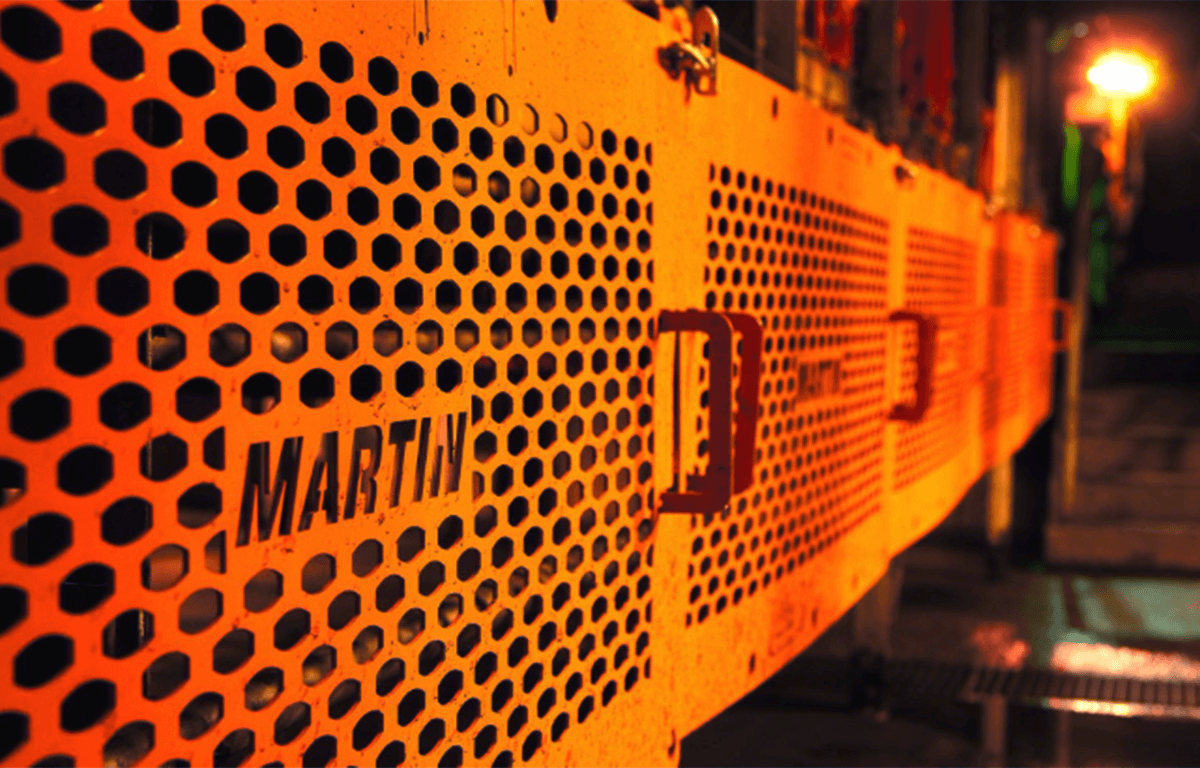

- ApronSeal ™ Dual Skirt

- Dust collection bag

Band Alignment.

- Martin® Tracker ™ Alignment

Band cleaning.

- PD QC1 ™ Cleaner

RESULTS

After rehabilitation of the area and installation of the Martin® equipment, a significant improvement can be observed in the area, the dust emission is minimal, as well as the loss of material that has been reduced by 85%, the area is clearly cleaner and safer for the workers, the cleaning work was almost completely reduced, thus eliminating the unplanned stops to accomplish this task, taking advantage of the workers’ abilities in other activities. The customer mentioned that he was very satisfied with the results, mainly due to the operative part and the reduction of cleaning time.